황동 공압 피팅은 정말 멋집니다! 마치 퍼즐 조각처럼 기계나 시스템의 분리된 부분들을 연결해주는 역할을 합니다. 공압 시스템의 모든 부품들이 어떻게 결합되어 움직임을 만들어내는지 궁금해 본 적이 있나요? 황동 공압 피팅은 모든 것이 연결된 상태로 문제없이 작동하도록 해줍니다.

브래스 공기압 피팅의 좋은 점은 매우 강하고 오래 사용할 수 있다는 것입니다. 이러한 피팅은 높은 압력을 견딜 수 있으며 외부의 압력이나 힘에 의해 쉽게 파손되지 않습니다. 이는 공기압 시스템이 물체를 움직이기 위해 공기 압력에 의존하기 때문에 중요한데, 따라서 피팅은 압력을 견디면서 파열되지 않을 수 있어야 합니다.

브라스 공압 피팅의 또 다른 장점은: 절대 부식되지 않는다는 것입니다. 즉, 물 근처나 거친 지형에 있어도 절대 손상되지 않죠. 이는 공장에서 건설 현장에 이르기까지 다양한 환경에 이상적으로 적합하다는 의미입니다.

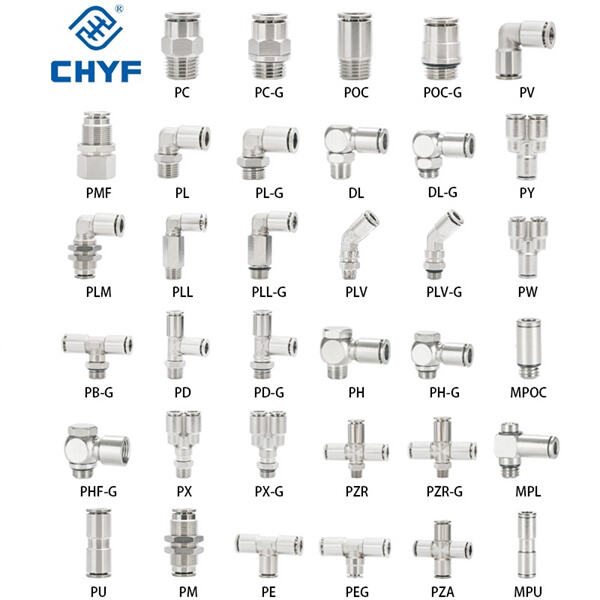

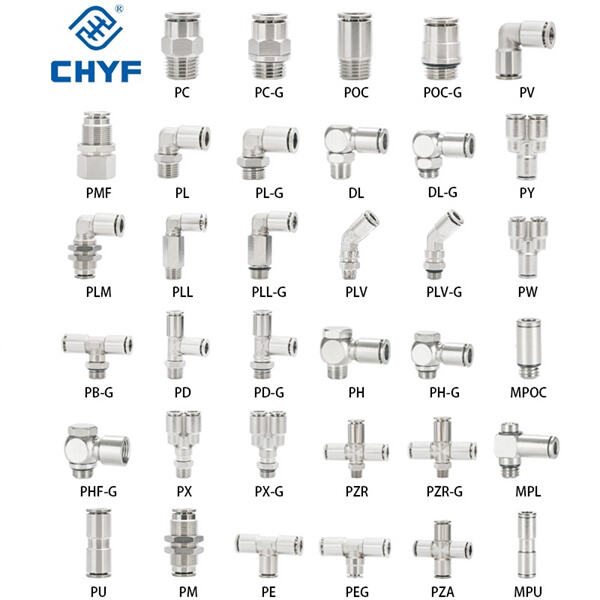

엔지니어와 정비사들이 브라스 공압 피팅이 제공하는 혜택을 좋아하는 이유는 다양하지만, 자주 사용되는 8가지 이유를 아래에서 확인할 수 있습니다. 이러한 피팅은 단순한 공기 압축기부터 복잡한 기계까지 다양한 곳에서 작동할 수 있습니다. 사용 중인 공압 시스템의 종류와 관계없이 브라스 피팅은 일반적으로 안전한 선택입니다.

브라스 공압 피팅은 자동차 엔진이나 엘리베이터와 같은 모든 종류의 기계에서 볼 수 있습니다. 공장, 건설 현장과 같이 공기 압력을 이용해 도구를 작동시키는 분야에서 널리 사용됩니다. 기계는 브라스 공압 피팅 없이는 효과적으로 작동할 수 없습니다.

브라스 공압 피팅은 가공 공정을 통해 솔리드 브라스(황동)로 만들어집니다. 이는 정확한 형태를 얻기 위해 브라스를 절단하고 드릴링하는 과정을 포함합니다. 이 공정은 극도로 정밀해야 합니다. 단 한 번의 실수로도 피팅이 제대로 맞지 않을 수 있습니다.

공압 시스템(그것은 단순히 공기 압축기일 수도 있음)이 있거나 공압 작동 부품이 있는 기계만 있다면, 저희가 보기에는 황동 공압 피팅이 필수적입니다. 이러한 피팅은 시스템이 최고 성능을 발휘하는 데 필요한 동력과 가치를 제공합니다. 황동 피팅을 선택한다면, 시스템이 향후 오랫동안 효율적으로 작동할 수 있도록 보장할 수 있습니다.