Alguns aspectos essenciais devem ser considerados ao selecionar a válvula solenoide correta para os seus sistemas pneumáticos ou hidráulicos. O que são Válvulas Solenoides: As válvulas solenoides controlam o fluxo de gás ou fluido em um dispositivo. Escolha Acerte de Primeira e ela funcionará corretamente, será incrivelmente rápida. Neste artigo, analisaremos vários fatores que você deve considerar ao escolher válvulas solenoides para o seu sistema.

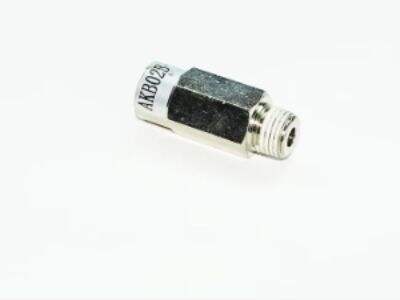

Pare sua Busca por Válvulas Solenoides Aqui

Primeiro, Tamanho: A válvula deve ter um tamanho compatível com o tamanho dos tubos ou tubulações do seu sistema. Uma válvula subdimensionada limitará o fluxo e uma válvula superdimensionada pode fazer com que o sistema funcione de forma ineficiente.

Classificação de Pressão — Confirme se a válvula solenoide é classificada para suportar a pressão do seu sistema. Se for classificada para uma pressão inferior, a válvula poderá falhar ou vazar, fazendo com que o sistema se deteriore.

Taxa de Fluxo: Considere a quantidade de ar ou líquido que deve passar através da válvula. É importante selecionar uma válvula com um fluxo adequado para garantir que o sistema funcione como deveria.

Tensão do Seu Sistema: Como as válvulas solenoides operam usando eletricidade, você precisará escolher uma válvula que opere na tensão do seu sistema.

Correlacionando Tipos de Válvulas às Suas Requisições de Pressão e Fluxo do Sistema

Uma válvula solenoide de 2 posições possui duas portas, T e A. Uma válvula solenoide de 3 vias também possui duas portas com T (entrada) e A, mas permite que o fluxo da saída retorne por uma abertura comum de escape denominada ventilação. Cada tipo foi projetado para seu método específico de controle de ar ou líquido. Escolha um válvula de controle pneumática para o seu sistema que atenda aos critérios de pressão e vazão, e tenha o percurso de fluxo desejado.

Como Selecionar Corretamente o Tamanho da Válvula Solenoide para Máxima Eficiência?

O processo de dimensionamento de uma válvula solenoide inclui a determinação do controle da vazão e da queda de pressão na válvula. Dimensionar sua válvula: dimensionar corretamente a válvula garante que ela opere de maneira eficaz e responsiva dentro do seu sistema. Se as válvulas forem muito grandes (superdimensionadas), você perderá energia desnecessariamente através da válvula, e se forem muito pequenas (subdimensionadas), poderá haver quedas de pressão e ineficiência.

Seleção de Materiais dos Componentes da Válvula Solenoide para Torná-la Duradoura

O material dos componentes da válvula determinará por quanto tempo sua válvula solenoide durará e o que ela poderá fazer. Diversos materiais podem resistir a diferentes temperaturas, pressões e produtos químicos. Selecione uma válvulas pneumáticas com materiais adequados à sua aplicação para que não se deteriore muito rapidamente.

Solução Personalizada de Válvula Solenoide com Base em Necessidades de Aplicação Exclusivas

Às vezes, válvulas solenoides padrão podem não ser suficientes para atender às exigências do seu sistema. Em alguns casos, será necessária uma solução individualizada para atender a necessidades especiais de aplicação. Com uma válvula solenoide personalizada, ajustada exatamente ao seu tamanho, vazão, pressão nominal e quaisquer outros requisitos necessários para o seu sistema.

Em resumo: escolher a válvula solenoide correta para o seu sistema pneumático ou hidráulico é de importância fundamental para garantir o funcionamento perfeito e o desempenho ideal. Ao selecionar uma atuador de válvula pneumática , pense em parâmetros como dimensão, classificação de pressão, vazão, tensão e material. Selecione o tipo correto de válvula para as pressões e vazões do seu sistema, dimensione a válvula corretamente para que seu desempenho seja otimizado, escolha o material adequado para maior durabilidade. Atenda necessidades que não podem ser satisfeitas com a oferta padrão de produtos por meio de uma solução personalizada. Com esse procedimento em mente, você pode manter seu sistema no melhor de sua capacidade, caso deseje funcionar em conjunto com a válvula solenoide da CHYF.

Sumário

- Pare sua Busca por Válvulas Solenoides Aqui

- Correlacionando Tipos de Válvulas às Suas Requisições de Pressão e Fluxo do Sistema

- Como Selecionar Corretamente o Tamanho da Válvula Solenoide para Máxima Eficiência?

- Seleção de Materiais dos Componentes da Válvula Solenoide para Torná-la Duradoura

- Solução Personalizada de Válvula Solenoide com Base em Necessidades de Aplicação Exclusivas