Tel: +86-577 61727673

Email: [email protected]

Tel: +86-577 61727673

Email: [email protected]

When you imagine machines moving, you might think of large gears turning or wheels spinning. But have you ever heard of a pneumatic linear actuator? It’s a big word but I’m going to keep it simple!

Visualize the fact that you are holding a toy car that you’re able to drive around with a remote. The car goes forward or backward when you hit a button. It also turns out that pneumatic linear actuators operate on the same baseline principle! They assist machines in moving by means of air pressure.

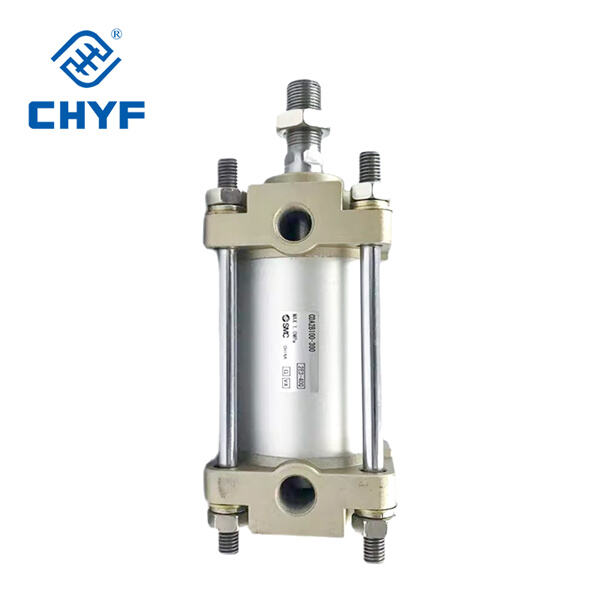

These actuators include a cylinder and the up-and-down motion creates a pushing/pulling motion on a rod. As air enters the cylinder, it pushes the rod out. Then, as the air comes back out, it sucks the rod in. This is another heavy thought, but necessary for machines to move just right!

Let’s take a look at now, how pneumatic linear actuators can take machines to the next level! Consider a robot arm that has to smoothly lift things up and down. Pneumatic linear actuators would enable the robot arm to be able to move the same way it should.

Automation is when machines can work by themselves without always needing help. That's where pneumatic linear actuators come in very handy! These actuators make machines go faster and they help to make machines work safer.

In jobs like manufacturing and assembly, speed and precision are crucial. Machines can do this thanks to pneumatic linear actuators! They ensure that machines can work faster and with fewer mistakes.

You’ll find pneumatic linear actuators everywhere, from manufacturing cars to packaging food. They matter in many professions. Whether it’s the field of farming, in healthcare, or even in entertainment, these actuators help ensure that your task goes off without a hitch.